As one of the most essential industries during the pandemic, manufacturers have experienced their share of challenges since early 2020 – from worker shortages and new safety protocols to supply chain issues and rising inflation rates. While it’s unusual to see positive economic gains at the same time as historic labor and supply chain challenges like these, this happens to be the trajectory for the U.S. manufacturing industry emerging from the pandemic. The industry’s recovery gained momentum in 2021 through rising demand. Manufacturing businesses had to respond quickly to the changes in order to survive and thrive. Industrial production and capacity utilization surpassed pre-pandemic levels midyear last year, and coupled with strong increases in new orders for all major subsectors, all signs point to continuing growth.

However, optimism around revenue growth may be held in check by caution from ongoing risks. Workforce shortages and supply chain instability are reducing operational efficiency and margins. Business agility is critical for organizations seeking to operate through the turbulence from an unusually quick economic rebound and to hold the momentum into the next growth period. As manufacturing companies look not only to defend against disruption but strengthen their offense, we examine important trends for you to consider. Our deep dive into three of the industry’s major priorities uncovers the custom print opportunities that provide answers to their needs.

Read on to discover insights to assist you in being a valuable consultant to your manufacturing customers and prospects. Understanding what their priorities are and how you can provide solutions helps you increase engagement, establish solid relationships and boost your sales.

Priority #1 – Hire and retain a skilled workforce

The Great Resignation is real – and a serious concern for employers. According to a recent survey of over 2,000 employed workers, nearly three out of four full-time employees (74%) and more than half of part-time employees (51%) report that they are planning to quit their jobs in 2022. Overall, more than two-thirds of all employed workers (68%) say that they plan to leave their current job in the next 12 months.

Additionally, according to a Jobvite survey, 30% of new employees leave their jobs within the first 90 days of getting hired. A great way manufacturing companies can make a meaningful first impression with new employees is by providing “Welcome Kits” filled with branded essentials like pens, Post-it®️ Notes, coffee mugs, ID badges and t-shirts. Rewarding existing employees with company swag builds loyalty as well.

Here are some ways manufacturers can attract and retain qualified employees amid the staggering manufacturing labor shortages:

- Draw attention to job fairs and interview locations with Yard Signs, Banners and Feather Flags

- Spread the word about hiring events with full-color Posters, Flyers and Postcards

- Keep new hires organized with benefits and training materials in Presentation Folders

- Recognize employee milestones and accomplishments with acrylic, wood and metal Plaques and Awards

- Ensure compliance with state and federal labor law requirements, with a Labor Law Poster Subscription Service

All of the above help attract talent and create a workplace culture that makes employees want to stay.

Priority #2 – Workplace safety

Keeping employees safe and healthy helps manufacturers avoid the detrimental costs of lost productivity. Workplaces with successful safety and health management systems reduce injury and illness costs 20-40%. OSHA experts estimate that companies spend $170 billion each year on costs associated with workplace injuries and illnesses. These expenditures come straight out of a company’s profits and can impact sustainability.

Successful operations require clear communication whether in a warehouse, factory, loading yard or shipping area, or even in a break room. Clearly communicating where materials are located, providing warnings and offering regulatory guidance on site or instructions on machine operation is key. Keeping communications up-to-date is also important as processes may change with fresh inventory or a new machine, or there may be new critical notifications.

Here are some ways manufacturers can promote a safe and healthy work environment:

- Clearly mark walkways, restricted areas and social distancing requirements with durable full-color Floor Decals

- Provide reminders about health and safety expectations with full color Signs, Posters and Banners in break rooms and public areas

- Inform and direct employees and visitors with engraved Directional, ADA, Desk and Wall Signage

- Post safety notices on equipment with full-color Outdoor Labels, Reflective Labels, Tech Decals and Magnetic Signs

- Promote safety messages and certifications on Hard Hat Labels

Appropriate warehouse signage may be the most effectual and low-cost way to improve operational efficiency. Unfortunately, many facilities haven’t taken the time or effort to evaluate, improve or correctly implement signage for their workers or guests. This is a lost opportunity. Today, savings and a faster production time can mean the difference between profit and loss, therefore there has never been a better time to implement or update a manufacturer’s signage program.

Consider if the signs are resilient enough for the environment they are posted in. For many production environments, a paper sign just won’t last. A sign that will deliver reliable information over time is needed. This means using a durable material designed to endure even in potentially wet, dry, cold, toxic or dangerous environments.

Floor signage is another vital element. The floors in the manufacturing industry are large blank slates – however, the right signage is imperative. Take the environment into consideration with decals, stickers and signs made of slip-resistant material. If the area is wet, a sign on the floor can be a slip hazard. Readability is an important aspect. Depending on the lighting, a glossy or matte finish is needed to make the sign easy to read and not be distracting. Not all signs are created equal. We can help ensure you have a sign that lasts and works for each individual facility or area.

Priority #3 – Production and operational efficiencies

Manufacturers looking to capture growth and protect long-term profitability should embrace bringing operational efficiencies to scale and find production and cost efficiencies within all operations including the business offices. Administrative staff members are often stretched to the limit, so taking steps to make ordering, approving and re-ordering of a company’s printed materials quick, cost-effective and consistent is important. These operational efficiencies can be achieved by implementing a branded ordering site, as well as through custom forms and office supplies.

Here are some ways manufacturers can drive efficiency in business operations:

- Custom Business Forms give a branded and professional image to job applications, HR forms, invoices, order forms and requisitions

- Minimize repetitive messaging with a custom Stamp or Dater

- Identify plant visitors with fluorescent Visitor Badge Labels

- Custom Checks and Tax Forms simplify AP, payroll and tax processing

- Locate warehouse items efficiently with Rack Labels

Fortunately, the manufacturing industry is building back fast, undeterred by significant labor and supply chain challenges. To maintain this momentum, reflect on the trends and then offer solutions to help your manufacturer customers and prospects mitigate loss and risks and advance efficiency. Manufacturers who see the value in investing in their hiring/retention programs, employee safety and well-being, operational efficiency and vendor management programs will have a distinct advantage while emerging from the current environment.

Actions you can take today

- Subscribe to local or regional business publications. Business publications often highlight new and upcoming businesses, and announce changes such as mergers and expansions.

- Join your local Chamber of Commerce. Volunteer for the board or help with events to connect better with manufacturers in your region.

- Offer a complimentary audit of a business’s printed materials to evaluate consistency in branding and messaging, print quality and ordering efficiency.

How we can help

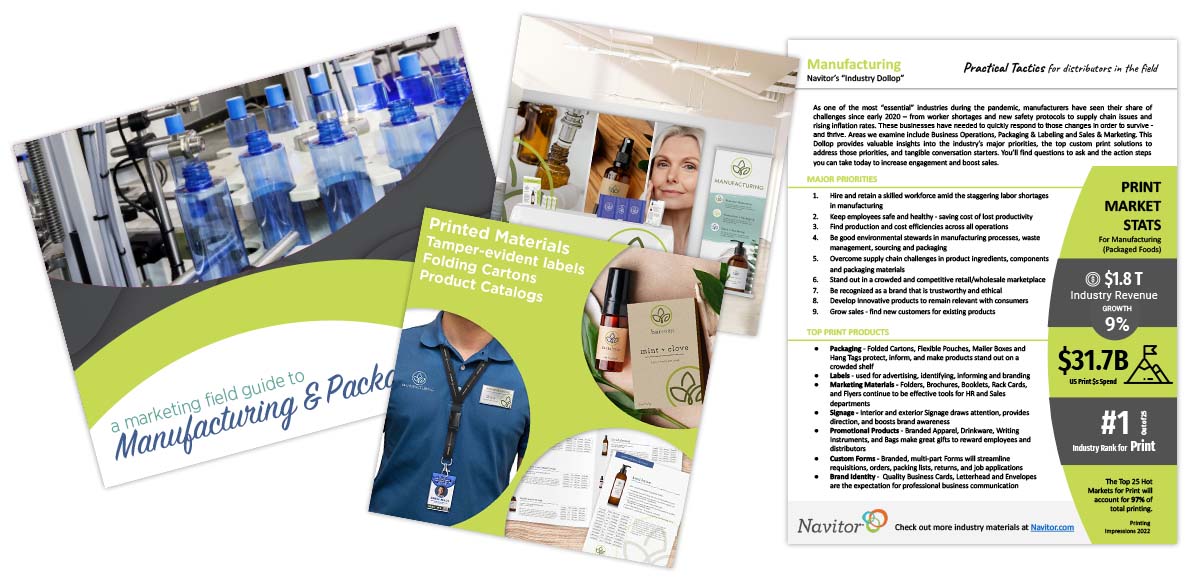

When it comes to vendors – less is more! Forming a strategic relationship with a print partner who can supply everything from Business Stationery and Forms to Signage, Labels and Packaging can lead to efficiency gains, optimized costs and stronger business outcomes. We offer a wide range of print solutions to help you consult and support your manufacturer customers so they can successfully navigate many of these operational challenges. Our sales support materials and industry research will help you start conversations and turn challenges into advantages so you too can recognize sales growth. We’ve compiled support materials like A Marketing Field Guide to Manufacturing & Packaging, product images, Manufacturing & Packaging social toolkit, and valuable Manufacturing & Packaging Dollop content that you can use to go to market today. Check it all out here.